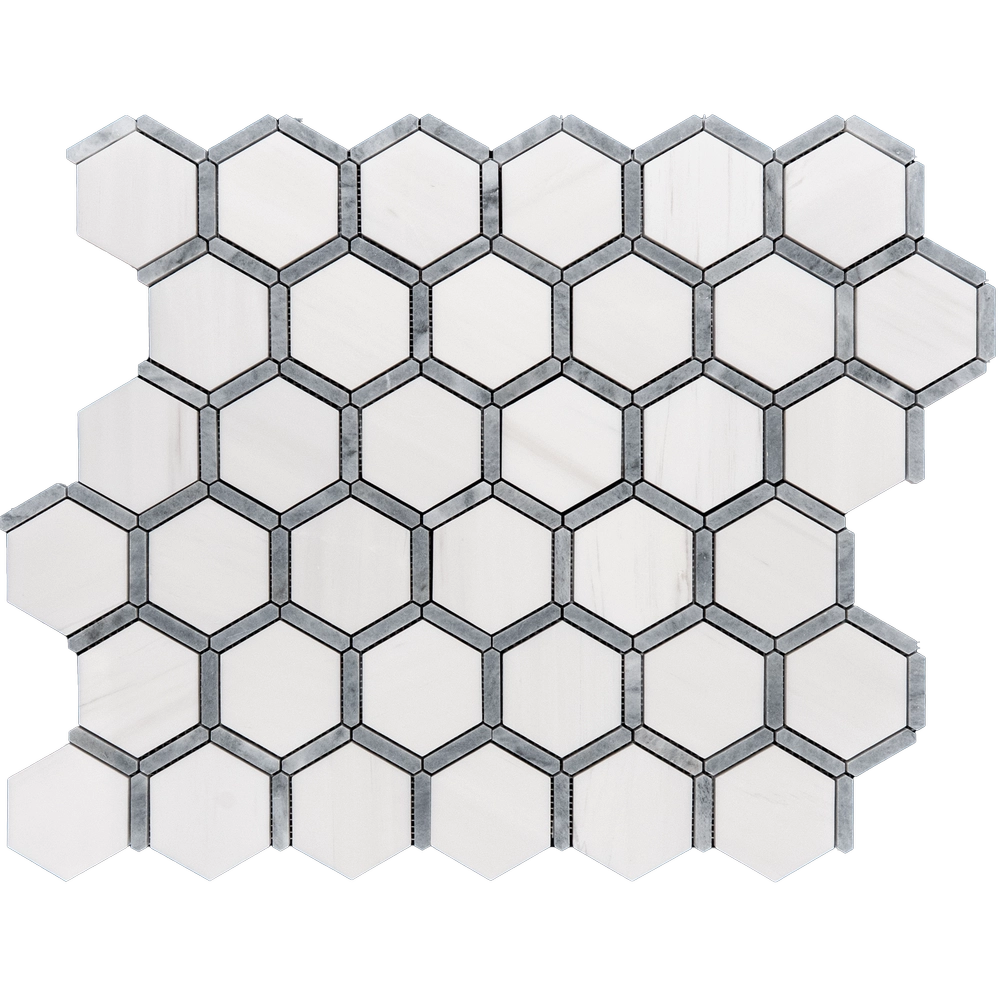

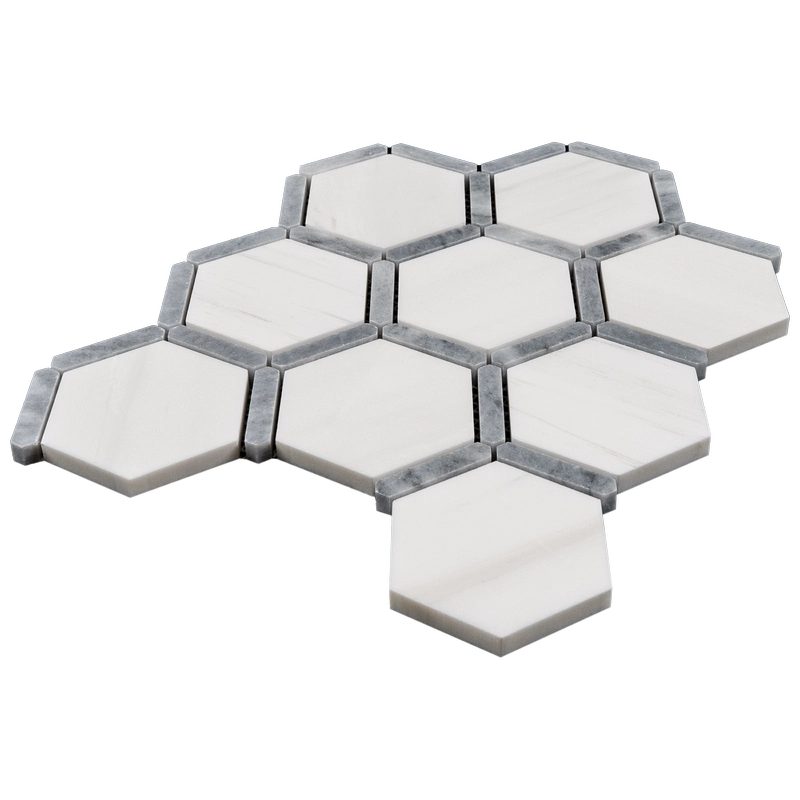

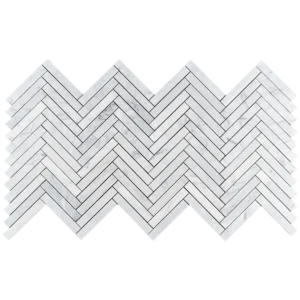

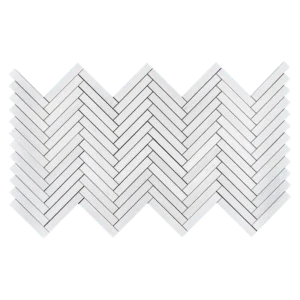

Installation Guide – Touch Polished Marble Mosaic Tile (Dolomite & Bardiglio)

Material Notes

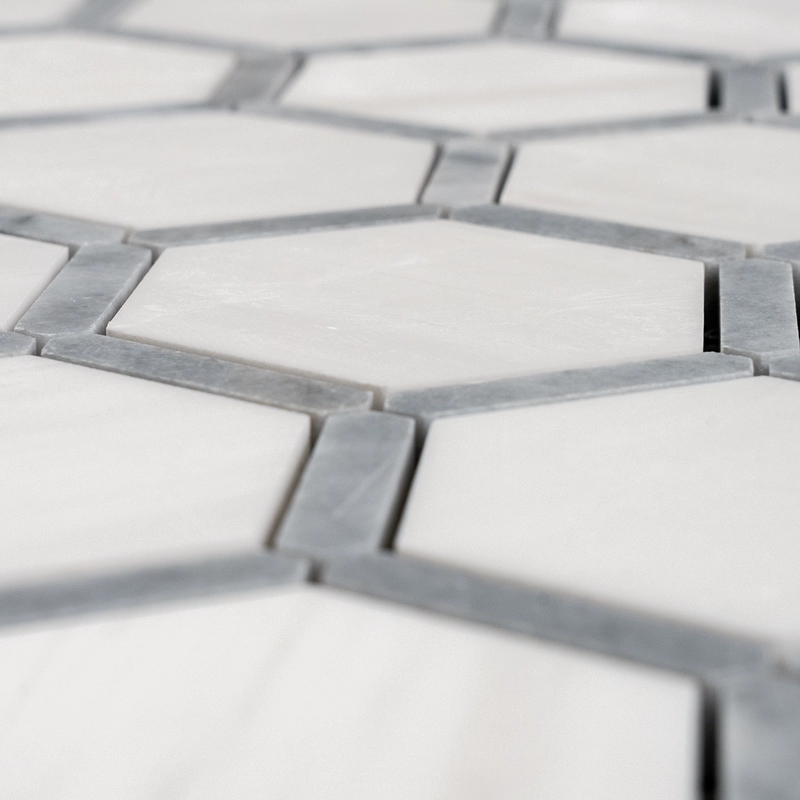

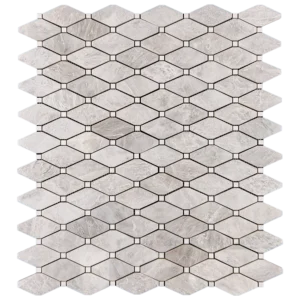

This mosaic combines Dolomite (white) and Bardiglio (grey) in a polished finish. Sheets are mesh-mounted (~12″x12″) with factory chip spacing; some may be paper-faced. Ideal for walls, backsplashes, shower surrounds, and light-traffic residential floors. Polished stone can be slippery when wet.

Step 1: Surface Preparation

Ensure substrate is clean, dry, structurally sound, and flat (≤1/8″ in 10′). Patch or skim as needed. Approved substrates: cement backer board, cured concrete, or ANSI-compliant mortar bed. In wet areas, apply an ANSI A118.10 waterproofing membrane.

Step 2: Dry Layout & Color Balancing

Dry-lay multiple sheets to blend Dolomite and Bardiglio chips evenly. Snap level reference lines for straight courses. Trim mesh edges and stagger sheet seams so grids disappear after installation.

Step 3: Adhesive (White Thin-Set) Application

Use a white, polymer-modified thin-set rated for natural stone (ANSI A118.4/A118.15). Avoid premixed mastics, especially in wet areas. White mortar prevents shadowing through Dolomite.

Trowel & Technique:

3/16″ V-notch or 1/4″×3/16″ V-notch on flat substrates.

Key in with flat side, comb in one direction, lightly flatten ridges to prevent telegraphing through chips.

Work in small areas (10–15 minutes) to prevent skinning.

Step 4: Setting the Sheets

Align sheets to layout lines; press with a rubber grout float or beating block for full contact. Maintain factory chip spacing—do not butt-joint. Back-butter individual chips if needed. Immediately clean any squeeze-through thin-set with a barely damp sponge/microfiber. For paper-faced sheets: set paper out, beat in, lightly wet after initial grab (~10–20 min), then remove paper and true joints.

Step 5: Cutting & Detailing

Use a wet saw with continuous-rim diamond blade; tape cut lines to minimize chip-out. For small trims, use mosaic nippers sparingly; dress cuts with a rubbing stone. Finish exposed edges with stone trim, metal profiles, or matching moldings.

Step 6: Grouting (Polished Stone)

Allow thin-set to cure (~24 hours). Use unsanded grout for joints ≤1/8″. Light-to-medium grey grout blends well; very dark grouts can frame the white chips—test first. Optional: apply marble-safe grout release or pre-seal to reduce pigment uptake, especially on Dolomite. Pack diagonally with rubber float; clean with minimal water to avoid washout/shading.

Step 7: Sealing

After grout cures (~72 hours), apply a penetrating, breathable marble-safe sealer. Re-seal periodically (every 1–2 years in wet or high-use areas).

Maintenance

Clean with pH-neutral, non-abrasive stone cleaners. Avoid acids, vinegar, bleach, or abrasive pads. In showers, squeegee/wipe dry to minimize mineral deposits. Use marble-safe scale removers if needed.

Movement Joints

Honor expansion joints and provide soft joints per TCNA EJ171 at perimeters, plane changes, and transitions. Use 100% stone-safe silicone at corners and where tile meets other materials.

Important Notes & Disclaimer

Natural stone varies in tone and veining; blend sheets before installation. Expect slight size/thickness tolerances common to mosaics. Always use white thin-set to preserve Dolomite’s appearance. Stonemarket USA is not responsible for improper installation or substrate issues. Professional installation is recommended.